Design Phase:

1. Requirement Analysis: Determine the purpose, scale, and geographical location of the hangar.

2. Conceptual Design: Includes overall layout, building area, height, span, door position, etc.

3. Structural Design: Design a suitable steel structure scheme, considering aspects such as strength, rigidity, stability, and seismic performance.

4. Material Selection: Choose appropriate steel materials, commonly including ordinary carbon structural steel and high-strength steel.

5. Drawing: Draw detailed construction drawings based on the design scheme, including component dimensions and connection methods.

Construction Preparation:

1. Site Clearing and Leveling: Clear and level the construction site to prepare for subsequent construction work.

2. Safety Inspection: Conduct safety inspections of the construction site to ensure safety during the construction process.

Construction Process:

1. Foundation Treatment: Including ground leveling, piling, and concrete pouring to form a load-bearing foundation support.

2. Steel Structure Installation:

o Prefabrication of Steel Components: Fabricate steel components according to design drawings and inspect them for acceptance.

o Pre-assembly: Pre-assemble to ensure the accuracy of the dimensions and positions of each component.

o Lifting and Installation: Use cranes to lift pre-assembled steel components into place and connect them with bolts and other fasteners.

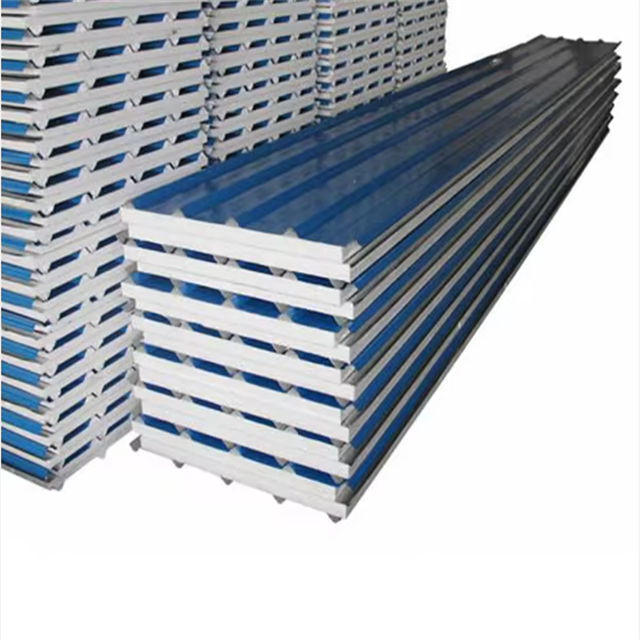

3. Roof and Facade Construction: Carry out waterproofing, insulation, and fire protection treatments for the roof, as well as the installation of exterior wall materials.

4. Interior Finishing: Including floor paving, wall painting, lighting installation, and pay attention to fireproofing and anti-electrocution safety measures.

5. Drainage System Installation: Ensure smooth drainage of the hangar.

6. Equipment Installation and Commissioning: Install and commission lighting, ventilation, fire protection, and other equipment.

Technical Points of Construction:

1. Compliance with Design Requirements: Operate according to design drawings and construction plans to ensure construction quality meets design requirements.

2. Safe Construction: Strictly follow safety operation procedures and take protective measures in the construction site.

3. Construction Quality Control: Strictly control construction quality by reasonably adjusting construction technology, sequence, and the use of construction machinery and equipment.

Safety Measures:

1. Personal Protective Equipment: Provide necessary personal protective equipment, including safety helmets, safety shoes, gloves, etc.

2. Site Fencing and Isolation: Fence and isolate the construction site and set up warning signs to ensure the safety of personnel and non-construction personnel.

3. Implement Safety Operation Procedures: Ensure no accidents occur during the construction process.

The above process covers the entire process from planning and design to completion of a steel structure hangar. Each link is crucial and must be carried out strictly in accordance with specifications to ensure the quality and safety of the hangar.