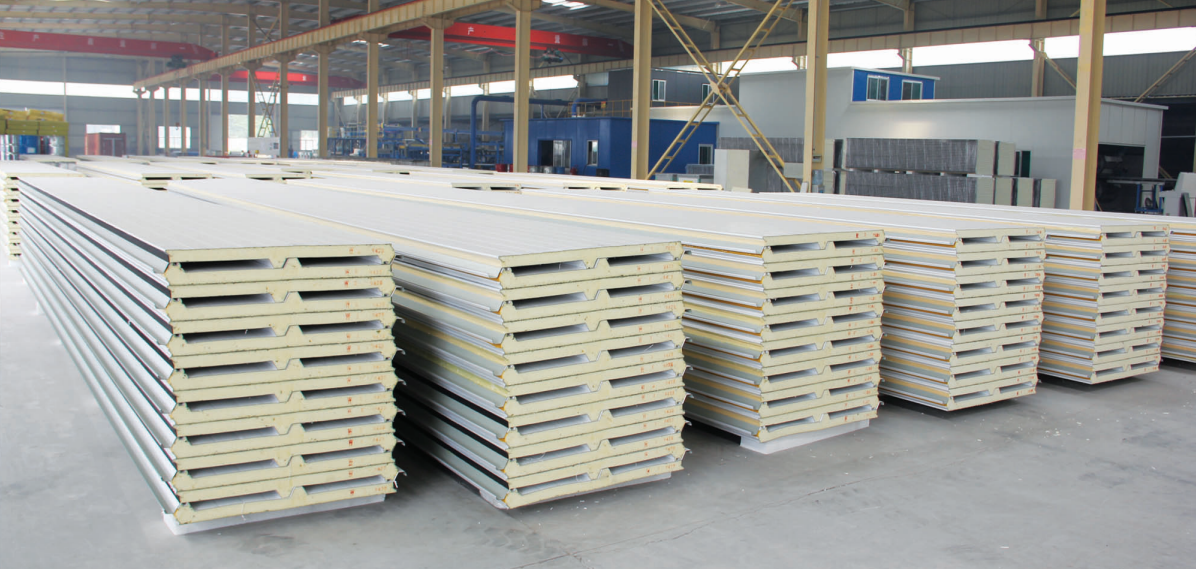

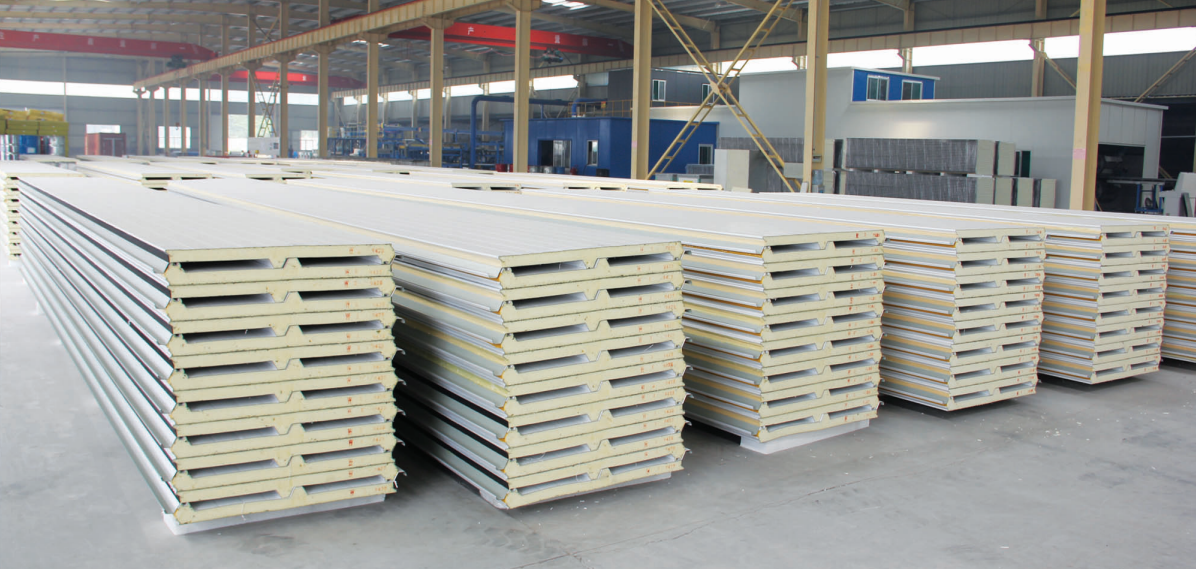

Product Introduction of Polyurethane Sandwich Panel

Our Polyurethane Sandwich Panel, also known as a PU sandwich panel, offers the best insulation performance, B grade fire resistance, light weight, and non-toxicity. It is widely used as pu insulated roofing panels in industrial buildings with high insulation requirements, as well as the other roofing of buildings.

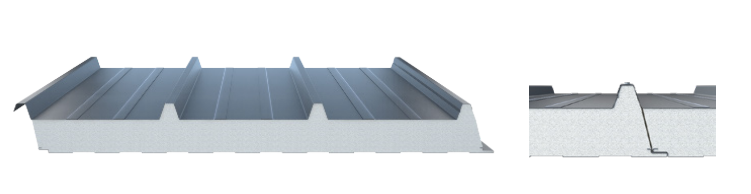

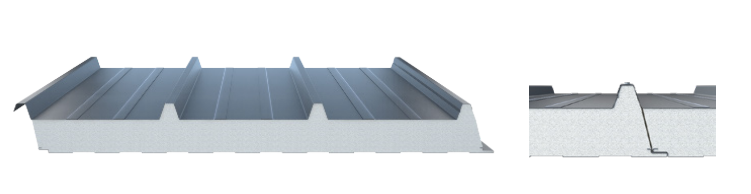

Connection Node

Parameters

Thermal Conductivity | 0.022 [W/m·K] |

Painting of steel plates | PVDF, SMP, HDP, PE. |

Standard Surface | PPGI, PPGL, Stainless steel

|

Thickness of steel plates | 0.4mm-0.7mm |

Thickness of core | 50mm/75mm/100mm/120mm/150mm |

Density of core | 40kg/m³; |

Effective width | 1000mm |

Production equipment

Characteristics of Polyurethane Sandwich Panel

Corrosion Resistance

The inner plate of our pu panel roofing can also use aluminum foil instead of steel plate, providing a smooth and beautiful indoor surface that effectively resists high temperature and high corrosion environments.

Reasonable Longitudinal Combination Design of PU Roof Panels

Our PU sandwich roof panel incorporates a bevel design at the small edge of the joint part, enhancing the strength of the panel.

Simple and Fast Construction of Heat Insulation and Fire Prevention

Our EPS roof panel meets the roof heat insulation and fire protection requirements in one go. The construction is simple and fast, effectively implementing the design significance of energy-saving roofing.

The Strength of the Polyurethane Roof Panel Itself

Our waterproof PU panel roofing features four-wave corrugations that increase the roof panel's resistance and bending moment deflection. This can save the amount of brown strip according to the situation.

Aesthetic Economy

Our waterproof sandwich panel offers a strong structure and rich color, reducing material loss. Furthermore, our PU roof Panel EPS Sheet is a perfect solution for those seeking a combination of aesthetics and functionality.

Our Heat Insulation PU Eeps Sandwich for Roofing is another excellent product in our range, offering superior insulation and waterproofing properties.