Product Overview of PU Polyurethane Sandwich

The PU Polyurethane Sandwich Panel is diligently engineered along with a complex design including galvanized steel slabs as well as a stiff polyurethane froth center. This innovative material is largely used across various markets, especially in cold storage resources, clean spaces, shops, and also various other atmospheres that require exceptional thermic insulation. Its adaptability makes it unbelievably appropriate for both Roof Polyurethane Sandwich Panel and also Wall Polyurethane Sandwich Panel treatments, taking care of unique construction needs.

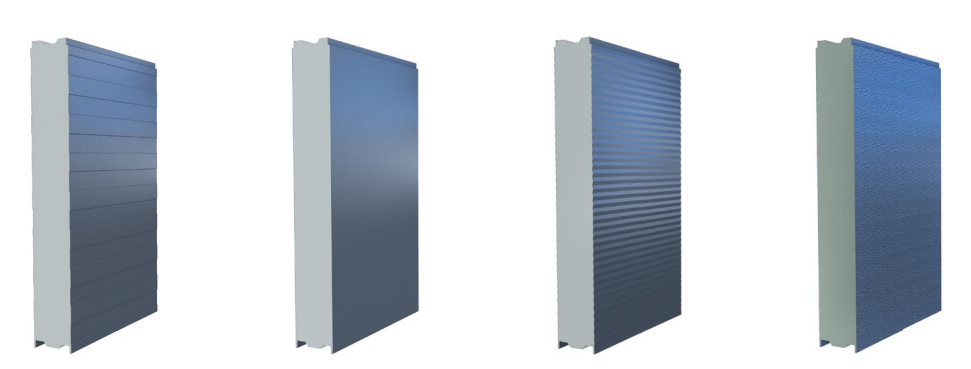

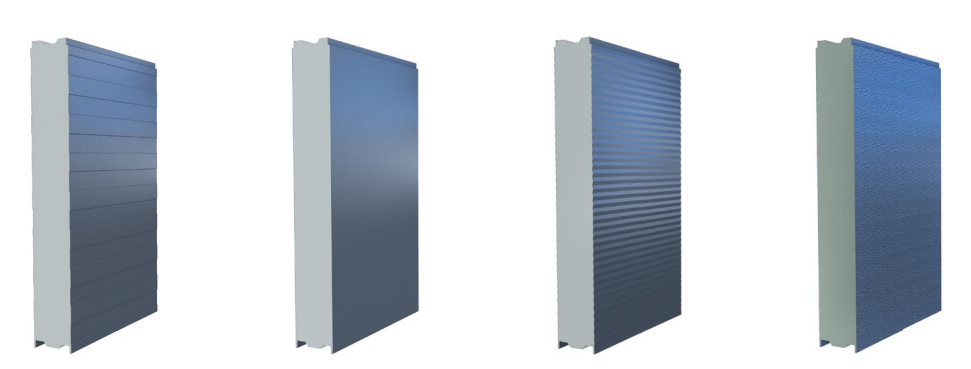

Diverse surface

Area Finishes for Thermal Insulation Polyurethane Sandwich Panel

When choosing a Thermal Insulation Polyurethane Sandwich Panel, it is imperative to take into consideration the surface area finish that best straightens along with your task's particular demands. The readily available choices include:

Requirement Surface Finishes: PPGI, PPGL, as well as Stainless Steel give strong security versus ecological aspects.

Steel Plate Coatings: Options like PVDF, SMP, HDP, and PE ensure longevity and visual allure in diverse uses.

These area therapies not simply enhance the panel's sturdiness but additionally result in its own overall visual value, creating them best for jobs where both performance as well as look are actually essential.

Technical Specifications of High Density Polyurethane Sandwich Panel

The High Density Polyurethane Sandwich Panel is created with accurate technological criteria to comply with strenuous sector standards:

Thermic Conductivity: 0.022 [W/m · K], making certain superb thermic efficiency.

Steel Plate Thickness: Ranges from 0.4 mm to 0.7 mm, providing structural stability.

Center Thickness: Available in 50mm, 75mm, 100mm, 120mm, 150mm, and also 200mm, allowing adapted protection efficiency.

Primary Density: 40kg/m ⊃3;, guaranteeing optimal rigidity and insulation.

Effective Width: 920mm/1120mm, created for modular compatibility as well as simplicity of installation.

These requirements highlight the panel's ability to provide steady efficiency all over a wide range of commercial and industrial apps.

Benefits of PUR Polyurethane Sandwich Panel

The PUR Polyurethane Sandwich Panel delivers a suite of benefits that are vital for both commercial and office apps:

Manager Insulation Performance: Provides outstanding thermal resistance, lowering power expenses.

Enhanced Fire Resistance: Meets rigorous protection standards, giving assurance in risky atmospheres.

Ingenious Pentane Technology: Positions this panel at the leading edge of environmentally accountable manufacturing strategies.

Exclusive Airtight Sealing: Ensures the greatest effectiveness in temperature-controlled atmospheres, critical for industries like food items storing and also drugs.

Energy Efficiency and also Cost Reduction: Engineered to minimize energy consumption, supporting each ecological durability as well as operational financial savings.

Structured Installation: Designed for quick deployment, dramatically minimizing work prices as well as task timetables.

Projects

Requests of Steel Structure Polyurethane Sandwich Panel

The Steel Structure Polyurethane Sandwich Panel is exclusively created for high-demand structural applications. Its High Density Polyurethane Sandwich Panel center imparts exceptional strength and also durability, making it suitable for heavy-duty industrial environments where lasting functionality is actually a concern.

Specialized Solutions: Standing Seam Roof Polyurethane Sandwich Panel & Hidden Screw Insulated Polyurethane Sandwich Panel

For jobs that require a seamless and safe and secure surface, the Standing Seam Roof Polyurethane Sandwich Panel is engineered to experience serious weather conditions while maintaining a classy appeal. Meanwhile, the Hidden Screw Insulated Polyurethane Sandwich Panel provides a soft, undisturbed surface, suitable for building uses where graphic beauty is as necessary as structural honesty.

Through selecting the proper PIR Polyurethane Sandwich Panel for your project, you make sure not just observance along with the greatest specifications of insulation as well as power efficiency yet additionally a substantial enhancement in the overall top quality and also sturdiness of the establishment.