Product Introduction

Cleanroom sandwich panel has a variety of core materials. According to different environments, fire prevention, heat preservation, noise reduction, moisture, etc. different core materials are selected to adapt to different clean room requirements. There are a variety of core materials, rock wool, PU, EPS, paper honeycomb, aluminum honeycomb. Hand made clean room sandwich panel is mostly used in clean room projects with high requirements on sound insulation, fire prevention, acid and alkali resistance, corrosion resistance and so on.

Parameters

Width | 980mm,1180mm |

Max Length | 8000mm |

Wall thickness | 50mm,75mm,100mm,150mm |

Steel sheet Thickness | 0.4-0.8mm |

Steel Sheet material | PPGI, Al-mg-Mn Alloy steel, Stainless steel |

Coating | PE,PVDF,HDP,PVC |

Core material | PU, Rockwool, Magnesium oxide board, Paper honey comb, Aluminium honey comb, Gypsum, EPS. |

Frame Thickness | 0.6mm/0.8mm |

Application

| Pharmaceutical Clean Room, Electronic Clean Room, Food clean Room. |

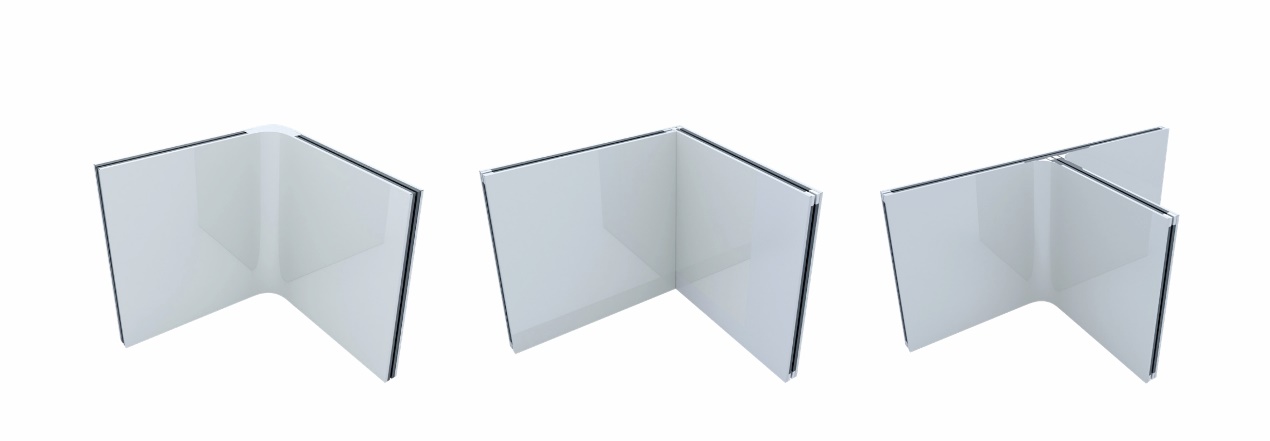

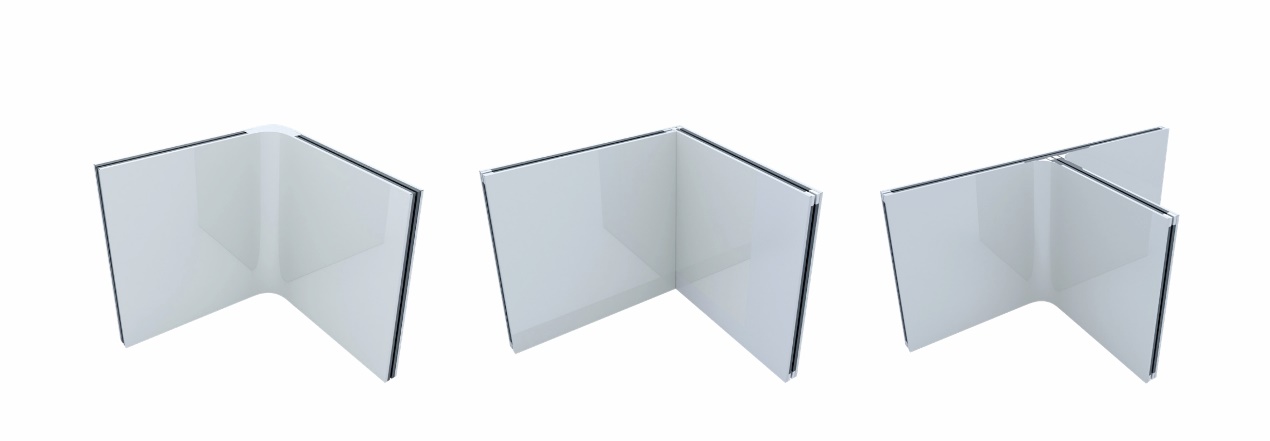

Integrated Angle Panel

Different from the traditional corner splicing combination, the integrated corner board makes the board into an overall corner board, so that the corner position is smooth and seamless transition, the interface is more tight, and the phenomenon of air leakage and joint dust accumulation is eliminated, which is convenient for cleaning and disinfection. The special insulation treatment of the integrated corner plate effectively avoids the common thermal bridge effect of the traditional corner.

Handmade Clean Room Sandwich Panel Characteristics

1. Panel material

Color coated steel plate, aluminum alloy plate and other materials with purification and cleaning function are used as panels

2. Core composition

It is made of rock wool, glass magnesium plate, aluminum honeycomb and other core materials

3. Excellent performance

Manual semi-automatic composite, accurate size, to ensure 100% inspection of each piece

4. Application

Suitable for the harsh winter indoor environment of the purification room project is the ideal clean room enclosure material