EPS Sandwich Panels, manufactured by Yantai Jedha Industrial and Trading Co., Ltd., are a highly adaptable and effective building material used in a variety of construction applications, particularly in roofing systems. Jedha has over 30 years of experience in producing steel structure systems and insulated sandwich panels. With a strong reputation for quality and service, Jedha's products are trusted by clients worldwide. The EPS sandwich panels offer exceptional thermal insulation, moisture resistance, and energy efficiency, making them an ideal choice for residential, commercial, and industrial buildings.

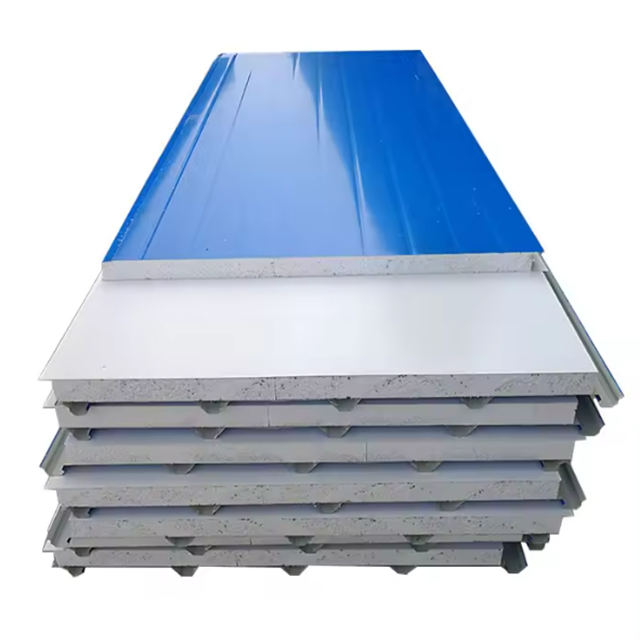

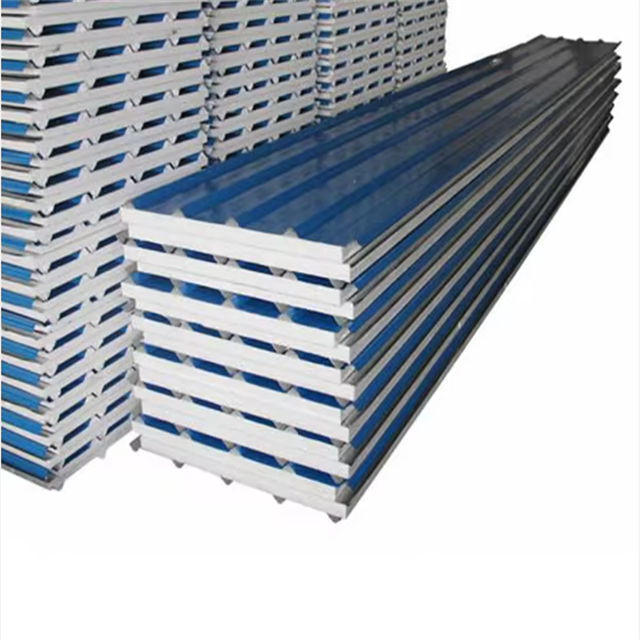

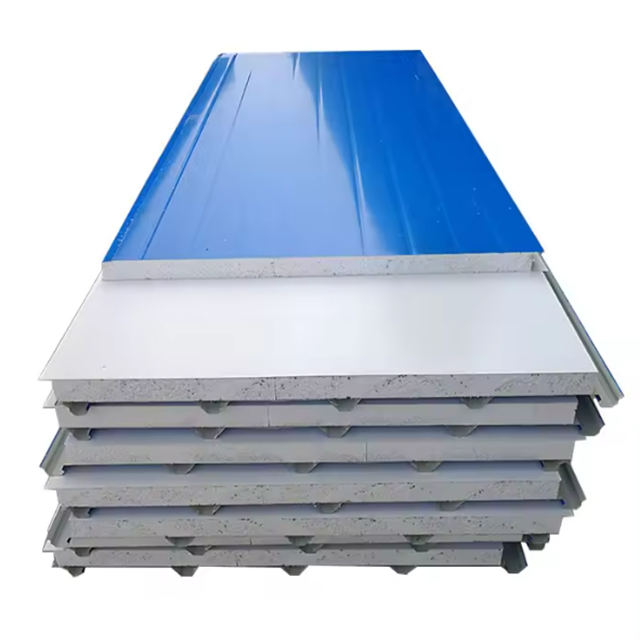

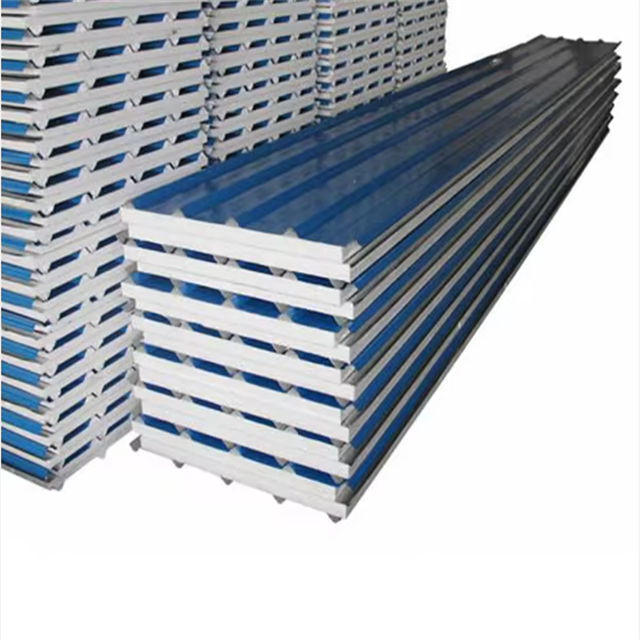

EPS sandwich panels are composed of expanded polystyrene foam (EPS) as the core material, sandwiched between two durable outer layers, usually steel or aluminum. This innovative design provides excellent thermal insulation, lightweight, and strength, all of which contribute to the overall energy efficiency and performance of the building.

In this article, we will explore how to install EPS sandwich panel roofing to ensure a long-lasting and secure roof for your construction project.

What is EPS Sandwich Panel Roofing?

EPS sandwich panel roofing refers to roofing systems made from panels that consist of a core material—expanded polystyrene foam (EPS)—which is enclosed between two metal or other durable exterior layers, typically steel or aluminum. This type of roofing panel is designed to provide excellent thermal insulation, soundproofing, and moisture resistance. The insulating properties of EPS make it an ideal material for various building types, including industrial, residential, and commercial structures.

Key Features of EPS Sandwich Panel Roofing:

Thermal Insulation: The EPS core provides high thermal resistance, making it an excellent option for temperature control inside buildings.

Moisture Resistance: EPS sandwich panels are designed to resist water penetration, making them suitable for use in humid environments.

Lightweight and Easy to Handle: The lightweight nature of EPS panels makes them easy to transport and install.

Durability: These panels are resistant to corrosion, decay, and environmental wear, ensuring a long lifespan for the roof.

Energy Efficiency: EPS sandwich panels contribute to the overall energy efficiency of a building by reducing heating and cooling costs.

Benefits of EPS Sandwich Panel Roofing

Before diving into the installation process, it's essential to understand the key benefits of using EPS sandwich panel roofing:

Energy Efficiency:

The thermal insulation provided by the EPS core significantly reduces energy consumption, making buildings more energy-efficient. This can lead to lower utility bills, especially in areas with extreme temperatures.

Speed of Installation:

EPS sandwich panels are pre-fabricated, which means they can be installed quickly. This helps to reduce the overall construction time for roofing projects.

Cost-Effectiveness:

Due to their ease of installation and long-lasting durability, EPS sandwich panels are often more cost-effective than other roofing options, especially in the long term.

Moisture and Fire Resistance:

EPS panels, particularly those designed with waterproofing features, offer excellent protection against moisture, ensuring the longevity of the roof. Additionally, fire-rated EPS sandwich panels provide an extra layer of safety.

Lightweight Design:

The lightweight nature of EPS sandwich panels makes them easier to handle during installation, reducing labor costs and the need for heavy equipment.

Step-by-Step Guide: How to Install EPS Sandwich Panel Roofing

Installing EPS sandwich panel roofing is relatively straightforward, but it does require careful planning and the correct tools. Follow this step-by-step guide for a successful installation process.

1. Preparation and Safety Measures

Before starting the installation, ensure that you have the following equipment:

Personal Protective Equipment (PPE): Safety goggles, gloves, hard hats, and steel-toed boots.

Tools: Drill, screws, screwdrivers, tape measure, level, and a cutting tool.

Cleaning Supplies: A broom or vacuum to clean the installation area.

Ladders and Scaffolding: Ensure that the work area is safe and accessible.

2. Inspect the Roof Frame

Before installing EPS sandwich panels, inspect the roof frame for structural integrity. Ensure that the framework is level, strong, and capable of supporting the weight of the panels. You may need to make adjustments to the frame if necessary.

3. Positioning the First Panel

Start by positioning the first EPS sandwich panel at one corner of the roof. Make sure the panel is aligned properly with the roof structure to avoid misalignment during installation.

4. Securing the Panels

Once the first panel is in place, secure it to the roof structure using screws or bolts. The type of fasteners will depend on the type of metal or material used for the exterior of the panel.

Place the fasteners at regular intervals to secure the panel firmly to the roof frame. Ensure that the fasteners are tight but not overly tightened, as this can damage the panels.

Use a drill with the correct bit size to pre-drill holes in the panel for the screws.

Ensure that each screw penetrates the roof frame deeply enough to hold the panel securely.

5. Installing Additional Panels

Once the first panel is secured, continue the process by placing the next EPS sandwich panel in line. The panels are designed with interlocking edges, which makes the process easier.

Repeat this process for the entire roof, securing each panel individually as you go.

6. Sealing the Joints

To prevent water infiltration and improve the overall insulation of the roof, it’s essential to seal the joints between the panels.

7. Trimming Panels

At the edges of the roof or around obstacles such as vents or skylights, you may need to trim the EPS sandwich panels to fit.

8. Final Inspection

Once all panels are installed, perform a final inspection to ensure that:

All panels are secure and aligned properly.

The joints are sealed effectively to prevent moisture infiltration.

The roof surface is level and clean.

FAQs

How Durable Are EPS Sandwich Panels for Roofing?

EPS sandwich panels are highly durable, offering excellent resistance to weathering, corrosion, and wear. With proper installation and maintenance, they can last for decades.

Can EPS Sandwich Panels Be Used in Extreme Climates?

Yes, EPS sandwich panels are suitable for use in both hot and cold climates. Their thermal insulation properties help maintain consistent indoor temperatures, even in extreme weather conditions.

How Do I Maintain EPS Sandwich Panel Roofing?

Maintenance of EPS sandwich panel roofing typically involves periodic inspections to ensure that the panels are secure and the sealant is intact. Cleaning the roof and repairing any damaged sections will help maintain the roof's performance.

Are EPS Sandwich Panels Fire-Resistant?

EPS sandwich panels can be manufactured with fire-resistant materials or coatings, making them suitable for use in buildings that require fire-rated roofing. Always check the product specifications for fire safety ratings.

Conclusion

Installing EPS sandwich panel roofing is an effective and efficient way to enhance the performance of your building's roof. The combination of excellent thermal insulation, moisture resistance, and easy installation makes EPS sandwich panels a preferred choice for many construction projects. By following the step-by-step guide provided in this article, you can ensure a secure, long-lasting, and energy-efficient roofing system for your building. Whether you're working on a residential, industrial, or commercial project, EPS sandwich panel roofing is a reliable solution that offers superior performance and durability.

At Jedha, we provide high-quality EPS sandwich panels and other building products that meet the demands of diverse construction projects. With our expertise and commitment to excellence, we ensure that your roofing system not only meets but exceeds your expectations for safety, efficiency, and longevity.