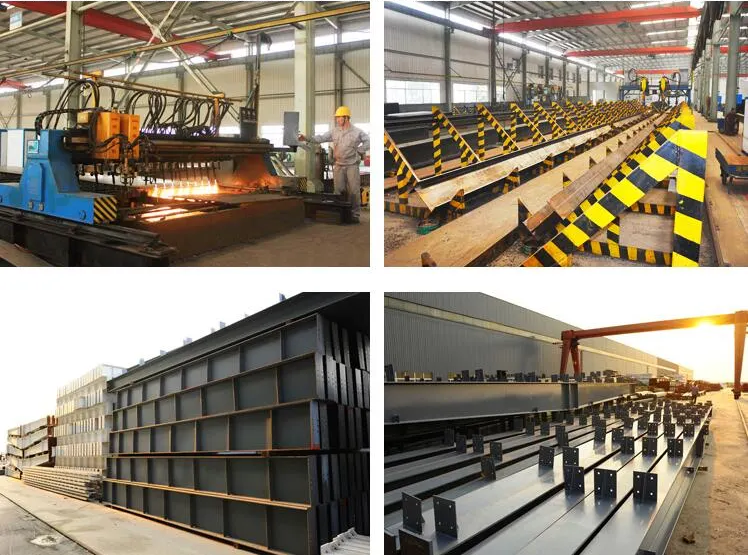

All the parts will be pre-made in the factory before being transported to the building site. The process of installation is quick and simple.

It will significantly reduce the time and money spent on constructing your buildings.

· Strong and long-lasting.

The steel structure is lightweight yet durable, and it requires minimal maintenance. It can be used for more than 50 years.

The prefabricated steel workshop can protect against outdoor elements and prevent water leakage. It also has exceptional resistance to fire and corrosion.

The steel structure can be easily moved and relocated, and it can be recycled without causing pollution.

The steel structure fabrication workshop can withstand strong winds, heavy snow, and has excellent resistance to earthquakes.

Yantai Jedha

is a well-established company with over three decades of experience in the manufacturing and trading of steel structure systems and steel sandwich panels. Our commitment to providing excellent service and high-quality products has earned us the trust of both domestic and international clients. We have successfully exported our products to various regions including Europe, America, Oceania, Africa, Middle East, and Southeast Asia, generating an annual revenue of more than fifty million RMB. With a vast inventory of over ten thousand tons of steel, as well as more than 40 state-of-the-art production lines for sandwich panels and corrugated steel, Jedha is a leading provider of Steel Structures, Prefab Houses, Sandwich Panels, PPGI, GI, Zinclume, Corrugated Sheets, and Decking floors, which are highly sought after worldwide.

FAQ

Q: Are you a factory or trading company?

A: We are a factory. We can provide one-stop service for our customer. And you can get the best price and competitive price.

Q: Do you accept container loading inspection?

A: You are welcomed to send an inspector, not only for the container loading, but any time during the production time.

Q: Do you offer designing service for us?

A: Yes, we could design full solution drawings as your requirements. They use software such as Auto CAD, PKPM, MTS, 3D3S, etc.

Q: what is the terms of payment?

A: Payment: L/C or by T/T(30% prepaid as deposit, the balance 70% before shipment)

Q: What is the delivery time?

A: Delivery time depends on order quantities. In general, the delivery time to the nearest seaport in China will be 30 days after receiving the deposit.

Q: How long can the space frame be used?

A: The use life of the main structure is the designed used life, that is 50-100 years (standard request of GB).

Basic Design Requirements |

1.Project location | 5.Length (side wall,m) | 9.Window quantity, size |

2.Snow load | 6.Width (end wall, m) | 10.Door quantity, size |

3.Wind load | 7.Wall Height (eave, m) | 11.Brick wall needed or not. If yes, 1.2m high or 1.5m high |

4.Seismic magnitude | 8.Middle column allowed or not | 12.Crane needed or not |

13. Insulating against heat. If so, EPS, fiberglass insulation, rock insulation, PU sandwich panels will be recommended; Otherwise, metal steel sheets will suffice. The latter option will be significantly cheaper than the former. |